- SFA=Simple Factory Audit

- EFA=Extensive Factory Audit

- SA=Social Audit

- LT=Lab Testing

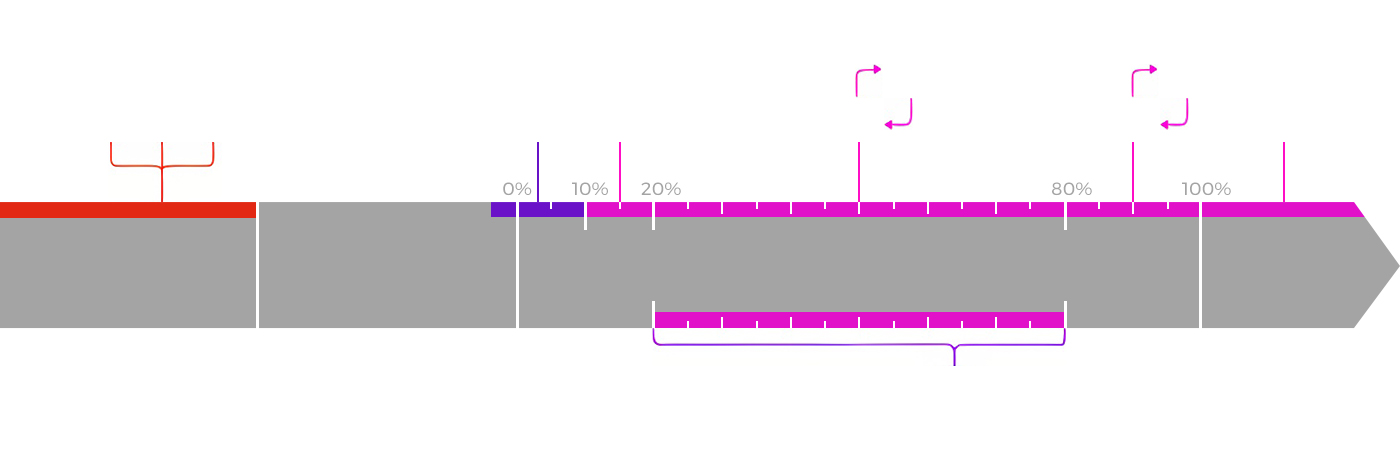

- PPI=Pre-production Inspection

- IPI=Initial Production Inspection

- DPI=During Production Inspection

- DSS=Defect Sorting Service

- PM=Production Monitoring

- PSI=Pre-shipment Inspection

- CLS=Container Loading Supervision