CE Compliance Test

CE marking is mandatory when importing goods manufactured in Asia to the European Union. CE marking can only be marked on consumer goods if they fulfill CE mark requirements. The product directives include the conformity to health, safety, and environmental legislation.

To verify the consumer goods, a notified body should perform health, environmental, and safety compliance lab tests.

Compliance tests in China and across Asia can only be conducted by laboratories that are notified bodies within the European Union. Compliance tests performed by non-notified bodies are void. TOPWIN proposes laboratory partners to offer consultancy and compliance tests that are fully recognised in the European Union.

Reach Compliance Test

In 2007, the European Union enacted the REACH Regulation (Registration, Evaluation, and Authorization of Chemicals) to regulate the use of chemicals in the supply chain to protect both the environment and the health of individuals. Manufacturers and importers can only sell in the European market once they have gathered information about their chemical substances and registered them with the European Chemical Agency (ECHA). They must show that the chemicals used in their product do not harm the environment or human health.

TOPWIN laboratory partners can provide consulting services for importers, distributors, and manufacturers to help with documents, independent certification, and other needs to comply with this regulation.

RoHS & WEEE Compliance Test

Coming into effect in 2006, the RoHS Regulations (The Restriction of Hazardous Substances Directive) is a European Union-wide directive that restricts the maximum allowable levels of lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr6+), Polybrominated biphenyls (PBB) and Polybrominated diphenyl ether (PBDE) in various types of electrical and electronic equipment. RoHS is closely linked to the WEEE Directive (The Waste Electrical and Electronic Equipment Directive), which sets collection, recycling, and recovery targets for electrical goods. To ensure that products such as appliances, IT equipment, consumer equipment, lighting equipment, electronic tools, toys, leisure and sports equipment, medical devices, monitoring and control instruments, and automatic dispensers will pass screening in Europe, our laboratory partners offer RoHS and WEEE testing.

RoHS compliance test is performed in China and across Asia by TOPWIN partners, including services such as XRF (X-Ray Fluorescent Analysis Microscope) and chemical analysis to provide importers and manufacturers with proof of compliance to these.

Hi-Pot Compliance Test

Hi-pot testing can be performed under laboratory conditions with certified third-party equipment and during a product inspection. Hi-pot lab testing is usually expensive but is the most reliable.

Hipot testing can help discover design flaws, defects, crushed insulation, stray wires, braided shielding, conductive or corrosive contaminates around the conductors, terminal spacing problems, and tolerance errors in IDC cables. If there is indeed a leakage in the insulation, this can cause the product to break down and is also extremely dangerous for anyone who would come into contact with the faulty product.

There are three common types of laboratory and on-site hi-pot tests:

Dielectric Breakdown Test

During this test, the voltage is increased until the dielectric fails or breaks down, thus determining the highest voltage the cable can handle. This test usually destroys the dielectric, so it is done on a random sample basis.

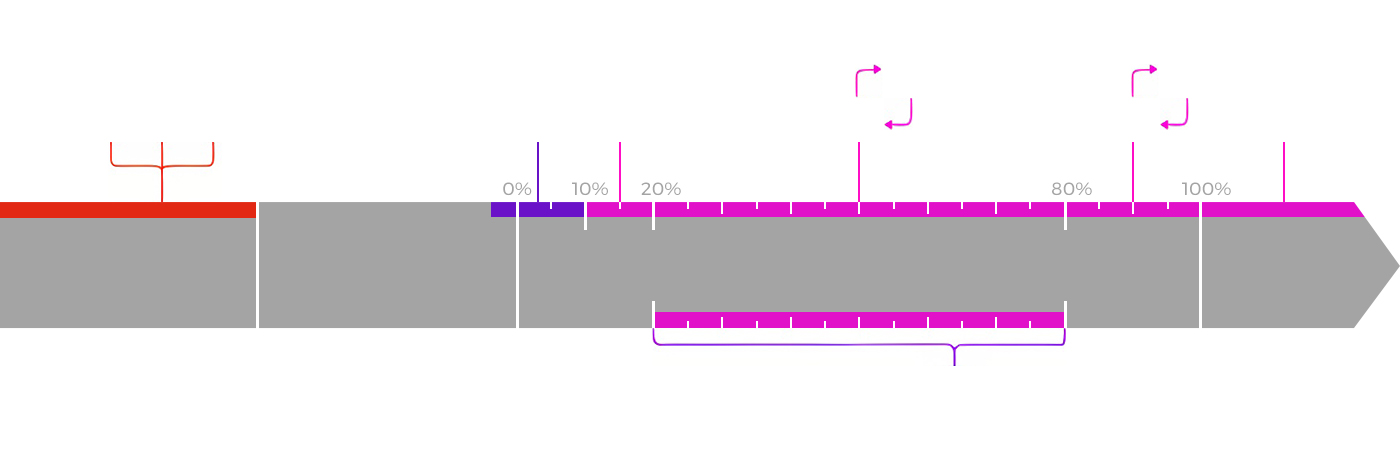

Dielectric Withstanding Voltage Test

This test is performed to see if the cable can withstand a certain amount of voltage for a required amount of time. The leakage is monitored during the test and must be below a preset limit to pass the test. The test in non-destructive.

Insulation Resistance Test

The purpose of this test is to determine the resistance of the product’s insulation. By measuring the voltage and the current, one can calculate the resistance of the insulation.

AZO Dyes Compliance Test

AZO dyes test is a common requirement from buyers sourcing in China and across Asia. AZO dyes are a group of synthetic nitrogen-based dyes that are often used in the textile industry. Amounts of AZO dyes above a certain level in textiles, leather, and other articles that come into direct and prolonged contact with the skin became illegal in 2003, with the EU Directive 2002/61/EC. Textile and leather products may contain other hazardous chemicals such as nickel, cadmium, organotin compounds, and lead.

Regulations on AZO dyes lab test were included in the 2009 REACH directive — see more information about our REACH compliance test.

Cadmium Compliance Test

The EU regulation for this highly toxic substance is under the REACH directive, as well as EN-71.

Food Contact Compliance Test

All materials that come into contact with food must be safe and should be manufactured to avoid any transfer of their components into food within the maximum quantities defined by the European Union. Food packaging materials should not transfer any of their ingredients into food that could endanger human health or change the composition, taste, or aroma of the food.

TOPWIN laboratory partners have extensive knowledge of international food contact regulations. Our partners can perform food contact compliance tests in China and across Asia according to various standards, including but not limited to EC No 1935/2004, EN 1186, EN 13130 for the European Union.

Phthalates Compliance Test

Commonly performed by our lab partners in China and across Asia, a phthalate compliance test is essential to ensure your products comply with the European Union regulation, set in 1999, and now covered by the REACH Directive.

Phthalates are mainly used as a component in plasticizers to increase flexibility, transparency, durability, and longevity, and as additives in certain plastics. They can be found in various products, especially baby’s toys, food packaging, footwear, garments, medical devices, and many more.

EN-71 Compliance Test

EN 71 standards, is the European Union regulation for toy safety that was enacted in 2009. Compliance with the standard is legally required for all toys commercialized or distributed in the European Union. Tests for toy safety include mechanical, physical, flammability, chemical, electrical, lead content, toxicological, radioactive, and packaging and labeling inspection and analysis. There are also specific standards for chemical games, finger paints, and activity toys that must be followed.